Table of Content

Digital Twin technology is becoming more popular with businesses and researchers. It’s being used in many industries to create accurate virtual models of real-world objects and processes. The Digital Twin market is also growing fast. In 2022, it was valued at $8 billion, and it’s expected to grow by 25% every year from 2023 to 2032.

More than a technological trend, digital twins are revolutionizing industries by helping organizations unlock efficiencies, reduce downtime, and make smarter decisions. By creating a real-time virtual replica of physical assets, systems, or processes, businesses can simulate, analyze, and predict performance with unprecedented accuracy.

This blog explores how businesses can use digital twin technology across industries. We’ll highlight real-world applications, their strategic advantages, and why this technology is critical for long-term success.

A digital twin is a virtual model of a real-world system that mirrors its behavior using real-time data, IoT (Internet of Things) devices, and advanced analytics. What sets it apart from traditional simulations is its dynamic nature. It continuously updates itself based on live data, allowing organizations to simulate various scenarios, predict outcomes, and optimize operations in real time.

Businesses today operate in environments of growing complexity and uncertainty. Digital twins offer a way to reduce risks, test scenarios, and enhance decision-making by providing actionable insights. The use of digital twins has moved far beyond manufacturing, where it first gained prominence.

Today, industries like healthcare, retail, aviation, and agriculture use digital twins to solve critical business challenges and build more resilient, adaptive systems. Whether it’s manufacturing precision components, predicting equipment failures, or optimizing city infrastructure, digital twins help you stay competitive in this data-driven world.

Digital twins function by integrating various technologies to replicate and analyze real-world processes in a digital environment:

By combining these technologies, digital twins can continuously evolve and provide accurate, up-to-the-minute insights that businesses can act upon.

Digital twins are redefining manufacturing by enabling real-time monitoring, predictive maintenance, and operational optimization.

Creating digital replicas of production lines allows businesses to simulate and test changes before implementing them, ensuring minimal disruption and reduced risk of errors.

A leading electronics manufacturer uses digital twins to monitor the performance of robotic arms in its production lines. By analyzing sensor data, the company reduces maintenance downtime by 30% annually.

Why It Matters

Digital twins of medical devices allow hospitals to monitor equipment performance, predict maintenance needs, and avoid service interruptions. Patient-specific twins simulate physiological responses to treatments, aiding in better clinical decisions.

A medical technology company develops digital twins for ventilators, tracking real-time usage data to ensure critical maintenance happens before breakdowns. Additionally, a hospital uses a digital twin of a patient’s heart to simulate surgery outcomes.

Digital twins are being used to design, monitor, and optimize urban infrastructure, making cities smarter and more sustainable. Planners create digital twins of transportation networks, utilities, and buildings to simulate how changes impact efficiency, sustainability, and residents’ quality of life.

A digital twin of Singapore’s urban infrastructure helps city planners simulate the impact of building a new subway line, leading to reduced traffic congestion.

Energy providers face challenges in managing aging infrastructure and balancing supply-demand dynamics. Digital twins provide a robust solution for these challenges. Digital twins of power grids, wind farms, and solar plants enable predictive maintenance and optimal energy flow management.

A renewable energy company creates digital twins of its wind turbines to analyze performance and schedule maintenance during low-energy demand periods.

Why It Matters

A wind energy company uses digital twins to monitor turbines’ health, predicting failures and scheduling maintenance during low-energy demand periods.

The aerospace industry relies heavily on precision and safety. Digital twins allow for real-time monitoring of aircraft and defense equipment to ensure reliability. Aircraft manufacturers use digital twins of engines to track performance metrics, predict wear and tear, and optimize fuel efficiency.

The Boeing 737-800 model is typically limited to carrying 79,000 kilograms of cargo safely. Challenge Advisory investigated whether this limit could be exceeded. Using digital twin technology, they successfully increased the safe cargo capacity by 23%, marking a major digital transformation for airlines operating this aircraft.

Digital twins help retailers and logistics companies streamline supply chain management and create better customer experiences. By simulating inventory levels and logistics routes, digital twins optimize supply chains, reducing costs and delays.

A global e-commerce company creates a digital twin of its warehouse to test different layouts for faster order fulfillment.

Digital twins are enabling precision agriculture by providing farmers with detailed insights into soil conditions, crop performance, and weather patterns. Farmers use digital twins to simulate crop growth under various irrigation and fertilization strategies.

A vineyard uses a digital twin to analyze microclimate data, predicting optimal harvesting times for better wine quality.

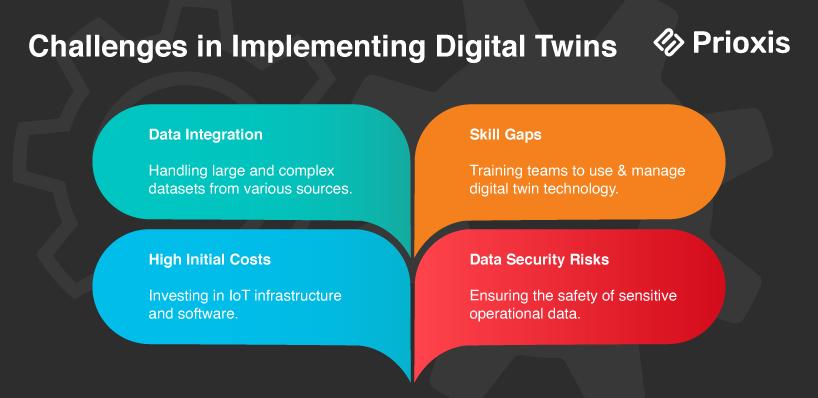

While digital twins provide immense value, businesses must overcome certain challenges for successful implementation:

As AI, IoT, and 5G continue to evolve, digital twins are set to play a larger role in business transformation. Key trends include:

Digital twins are moving beyond individual systems to represent entire ecosystems.

A factory’s digital twin could connect with supply chain twins to simulate and address inventory or shipping issues in real-time. Businesses can gain a holistic view of operations, leading to seamless collaboration and better decision-making.

AI-powered digital twins will soon make decisions and adapt without human intervention.

An energy grid’s digital twin could reroute electricity during outages or predict peak usage and adjust supply. Faster responses, fewer errors, and reduced dependence on human oversight.

Cloud-based platforms are making digital twins accessible to smaller businesses.

SMEs can now adopt digital twin solutions via affordable services like AWS IoT Twin Maker or Microsoft Azure Digital Twins. This levels the playing field, allowing businesses of all sizes to innovate and optimize operations.

Siemens: Automating Smart Factories

Siemens created digital twins of its production lines to simulate workflows and optimize configurations. Reduced errors, faster product rollouts, and increased adaptability to market changes.

GE Aviation: Minimizing Downtime

GE uses digital twins to monitor jet engines in real-time, tracking data such as temperature and pressure. It prevented unexpected failures, reduced downtime by 30%, and saved millions in maintenance costs.

Smart Dubai Initiative: Building a Smart City

Dubai created digital twins to manage traffic, energy, and infrastructure in real-time. Improved sustainability, reduced congestion, and enhanced urban planning efficiency.

Digital twins are transforming industries by bridging the gap between physical and digital systems. Adopting digital twins' technology not only solves today’s problem but also helps in future-proofing your operations. They allow businesses to simulate, predict, and optimize processes with real-time data. From manufacturing and healthcare to energy and urban planning, digital twins offer a versatile solution to complex challenges, helping companies make smarter decisions and achieve better outcomes.

For businesses, the advantages are clear. Digital twins reduce downtime, enhance operational efficiency, and provide a foundation for data-driven decision-making.

Whether you’re optimizing a single asset or transforming entire ecosystems, the potential is immense. Contact us today to learn how digital twins can help you innovate, grow, and lead in your industry.

Get in touch